Seven Reasons Why Dryer Belt Keeps Breaking Repeatedly

Typically, your dryer belt volition final as long every bit the dryer itself. So, patch they are relatively inexpensive too slow to supercede, if a dryer belt is repeatedly breaking, and so it’second time to open up upward the dryer together with investigate.

There are several potential reasons for repeated belt breakage; thankfully, nosotros’re here to intermission downwardly all the probable causes in addition to help yous place the reason for yours.

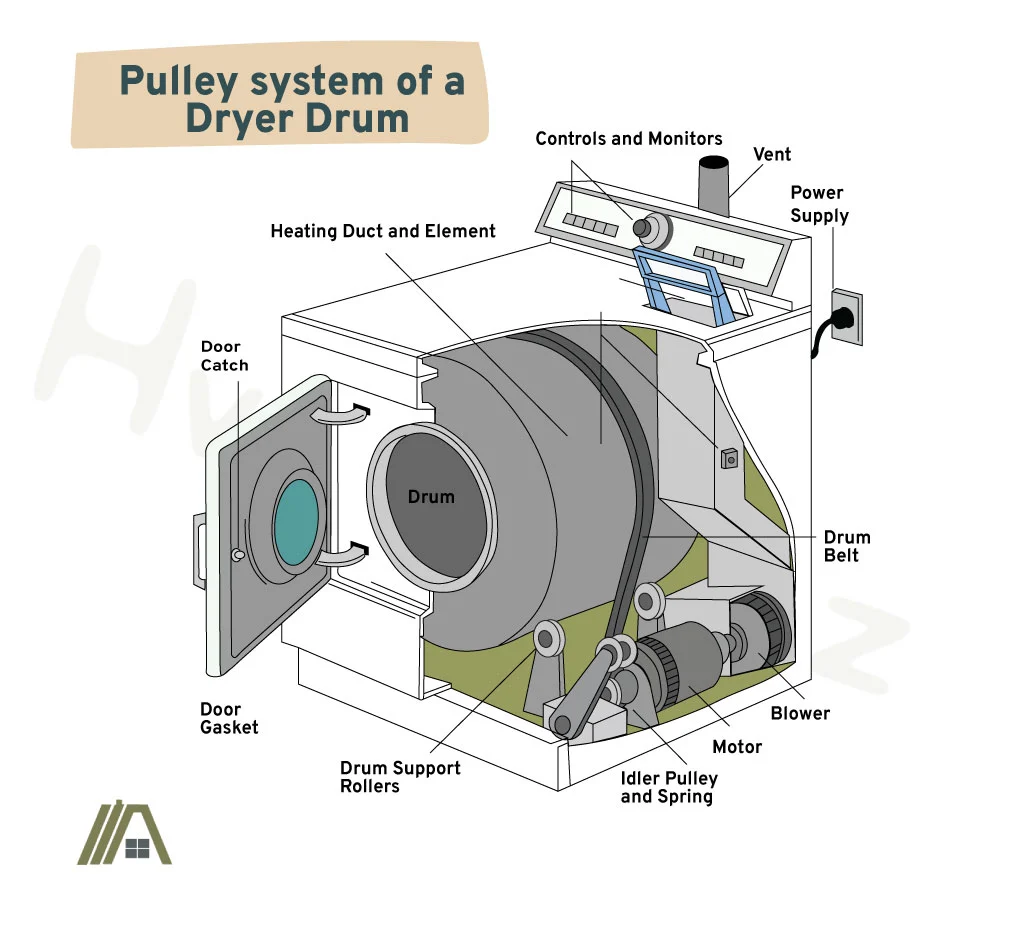

Dryer belts volition suspension time after fourth dimension if they are improperly installed, the wrong size for the dryer, or if the dryer is often overloaded. A broken pulley system, damaged drum felt seal, blocked blower bicycle, or seized drum rollers would besides movement the belt to go along breaking repeatedly.

What Causes the Belt to Break?

A dryer belt in optimal weather will final several years. While it volition, of course, however wear out over fourth dimension as well as potentially fifty-fifty snap, y'all take some other job on your hands if your belt is repeatedly breaking over a brusk period of time.

If historic period is not the reason for your snapped belts, so your job lies with tension and friction.

In other words, some other factor or ingredient is creating as well much tension or friction, making your belt wearable out in addition to neglect much sooner than it should.

vii Reasons Why Dryer Belt Keeps Breaking

1. Improper Installation of the Belt

While every function of your dryer may be perfectly functional, yous may nonetheless take a job if the belt is incorrectly installed.

First, ensure that your novel belt is placed the right mode upward. The side of the belt that is grooved or ridged should be placed inwards so that it is inwards contact with the drum together with pulley wheels.

If the belt is installed upside down, the grooves on the motor pulley tin burn down through the apartment side of your belt together with tear it into strips.

Secondly, yous should brand certain your belt is properly aligned. If the belt is placed off-centre on the motor or idler pulley, it may not necessarily pull itself into home as the dryer runs.

This would crusade your belt to endure sideways tension while the dryer runs in addition to the tension it is meant to handgrip, causing harm to pass more than quickly.

two. Overloading the Dryer

Overloading the dryer is an easy mistake and one that many people make. This may non be a large bargain if it exclusively happens one time or twice, but repeatedly overloading your dryer will for certain wearable down its components.

Overloading can fall out if the wear y'all position into the dryer is likewise heavy as well as wet or if yous merely home too many clothes inside instantly.

The excess weight of a too-total drum places an inappropriate amount of stress on your dryer’s components. The parts must endure more than friction too tension than they were meant to inwards gild to properly run and plow the drum–as well as we know what friction does to a belt.

three. Wrong Belt

While nearly dryers office very similarly on the inside, their office sizes will vary. The dryer belts are no exception to this.

Each dryer model is built to handle a sure amount of weight or to live capable of performing sure tasks. The size, weight, and forcefulness of each slice are chosen and manufactured to balance out alongside the other parts, creating a organisation that operates smoothly and efficiently.

Different models may postulate thicker or thinner belts to grip about weight, or they may be longer or shorter to match over certain drum sizes.

Belts besides accept varying types or sizes of grooves inward society to create roughly friction, or to agree perfectly into the matching grooves on the pulleys’ belt slots.

There are many unlike reasons ane belt differs from the next. However, using an incorrect belt for your dryer model volition essentially guarantee early breakage, every bit it is not designed to function inward tandem alongside the other parts.

So, belts are non interchangeable, and you lot require to identify the right size. If you lot are looking for help finding the correct belt for your dryer, I recommend reading through my ultimate take.

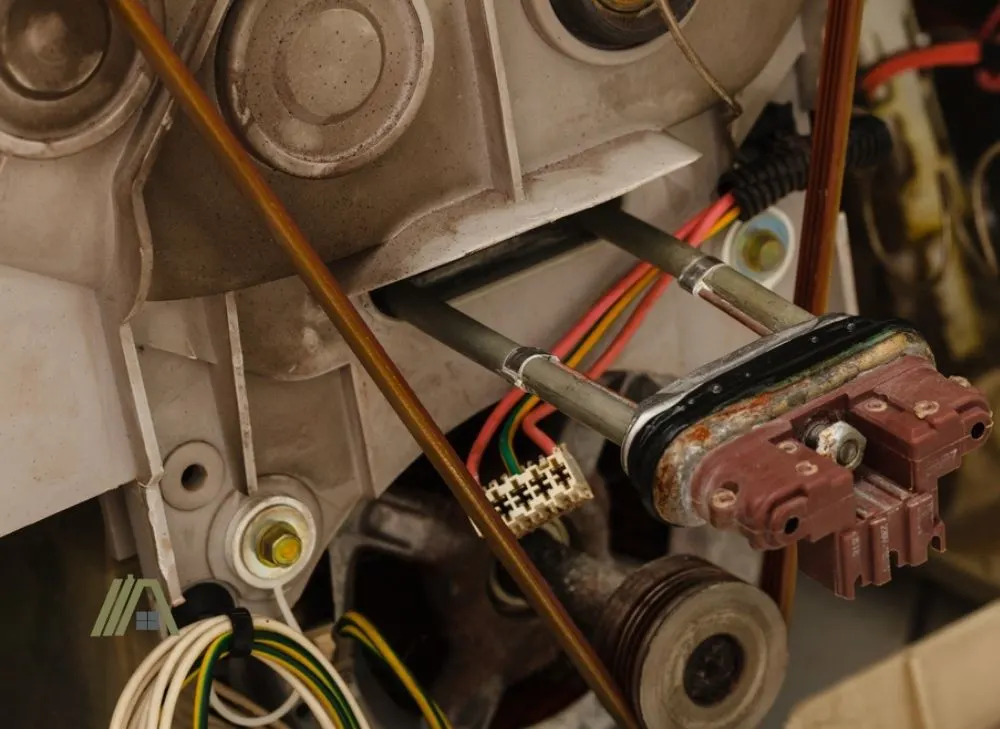

4. Broken Pulley

There are a few signs to scout out for that may betoken that the problem lies alongside your idler pulley or your motor pulley.

If your dryer rotates merely makes a squealing audio, or if it rotates but clunks intermittently, you ought to bank check too meet if your idler pulley or motor pulley are the event.

You will likewise want to check your pulleys if your drum does not rotate at all or if it spins when it is empty only non when in that location is a load within of it.

Your idler pulley may fail to function if there is a job with the pulley bearing or the spring.

As for the motor pulley, its grooves may article of clothing downwardly together with make it hard to “grip” onto and draw the belt.

While these are functional problems, it is likewise possible for lint to make upwards on your pulley organisation, drying it out in addition to increasing the level of friction that occurs.

five. Seized Drum Rollers

If y'all are hearing a thumping racket piece your dryer is running, yous may want to accept a await at your drum rollers to ensure that they are not the problem.

This thumping could indicate a flat topographic point on one or both of your dum rollers, which can go on if one of them has seized or stopped moving long enough to live worn downwardly.

While a flat place may look similar a child problem, the slight jostling together with drive that it causes tin be enough to stress out in addition to damage your belt much more rapidly than a polish rotation of the drum.

To ready this issue, yous’ll non alone involve to supersede the affected rollers simply as well cheque for as well as make clean off any hair or lint that has built upwardly around them.

Do non role lubricant on the dryer rollers no thing how tempting it may live. These lubricants, such every bit WD-twoscore are flammable as well as tin too movement as well as together on the rollers much faster.

Hair make-up is one of the nearly mutual causes of a roller seizing upwardly, then checking for make-upwards tin can forbid your new rollers from enduring the same damage.

six. Damaged Drum Felt Seal

If yous’ve always taken bill of the drum felt seal on the within of the door, yous may not see it to live a peculiarly integral part of your dryer’sec functioning.

In reality, this felt seal serves 2 major purposes. The outset is to foreclose vesture from finding its mode into the gap betwixt the drum too the door. The minute is to trim friction.

The placement of the seal keeps the drum from rubbing against the front end panel of your dryer. If the felt seal has fallen off or get misplaced, the drum’sec rubbing against the door panel may live creating drag.

This drag creates friction, too equally nosotros know, excess friction increases wear as well as damage to your dryer’sec components.

7. Blocked Blower Wheel

Last only non to the lowest degree, you will desire to bank check on your blower bicycle, peculiarly if you lot take noticed a high-pitched squealing racket, loud noise, or thumping noises piece running the dryer.

The blower cycle is meant to circulate the air inside your dryer too post it back out through the exhaust vent.

Much like other parts of your dryer, lint tin can build upward on the bicycle in addition to forestall it from blowing. It is as well capable of snagging modest items similar socks, hairballs, or dryer sheets.

If your blower cycle collects construct-upwards, it can drag on the motor and create problems amongst heat and friction. This could not entirely be the cause of a broken belt, merely it may live a fire adventure.

Additionally, if you take been noticing that your wearing apparel accept a long time to dry out or are coming out as well hot, that is some other sign that your blower wheel is the problem. This increased estrus or extra time running could likewise be contributing to your belt’sec article of clothing in addition to tear.

Sources

https://ars.repair/dryer-repair/checking-the-blower-wheel-for-lint-clogs-inwards-your-dryer/

https://bcalease.com/faq/troubleshooting-your-equipment-dryer/

https://www.doityourself.com/stry/iv-signs-that-you lot-necessitate-a-novel-dryer-blower-bicycle

https://homeguides.sfgate.com/dryers-pulley-broken-41150.html

https://homeguides.sfgate.com/how-to-know-when-to-supervene upon-a-dryer-filter-13768639.html

https://homesteady.com/info-12123535-use-felt-seal-dryer.html

https://www.youtube.com/lookout?v=7eY9kwK77KI

Comments

Post a Comment